Additive Manufacturing Services

At AECSS, we are pioneers in the realm of Additive Manufacturing, utilizing advanced technology to transform concepts into reality. Our Additive Manufacturing services offer unparalleled precision, speed, and customization, revolutionizing traditional production methods.

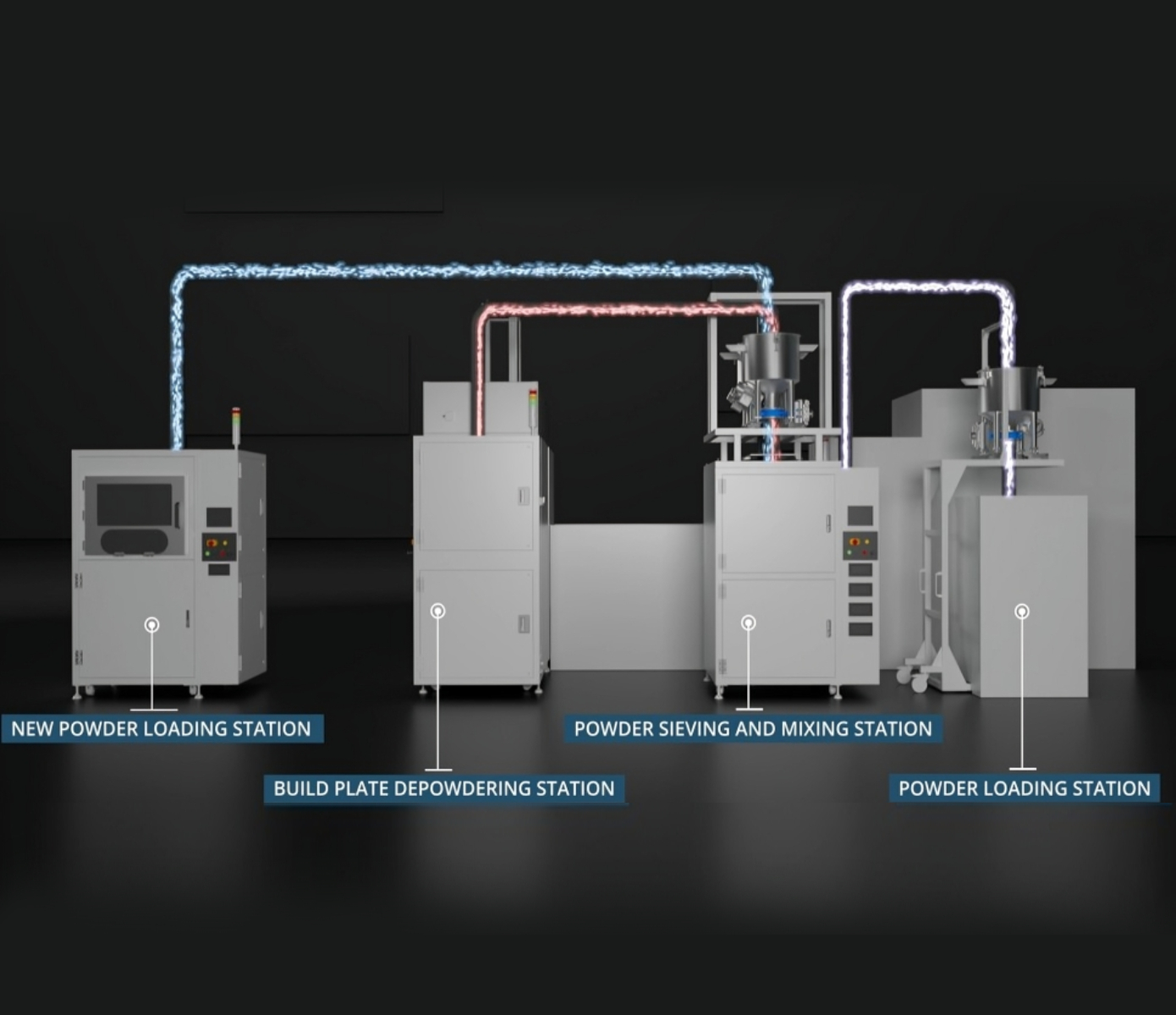

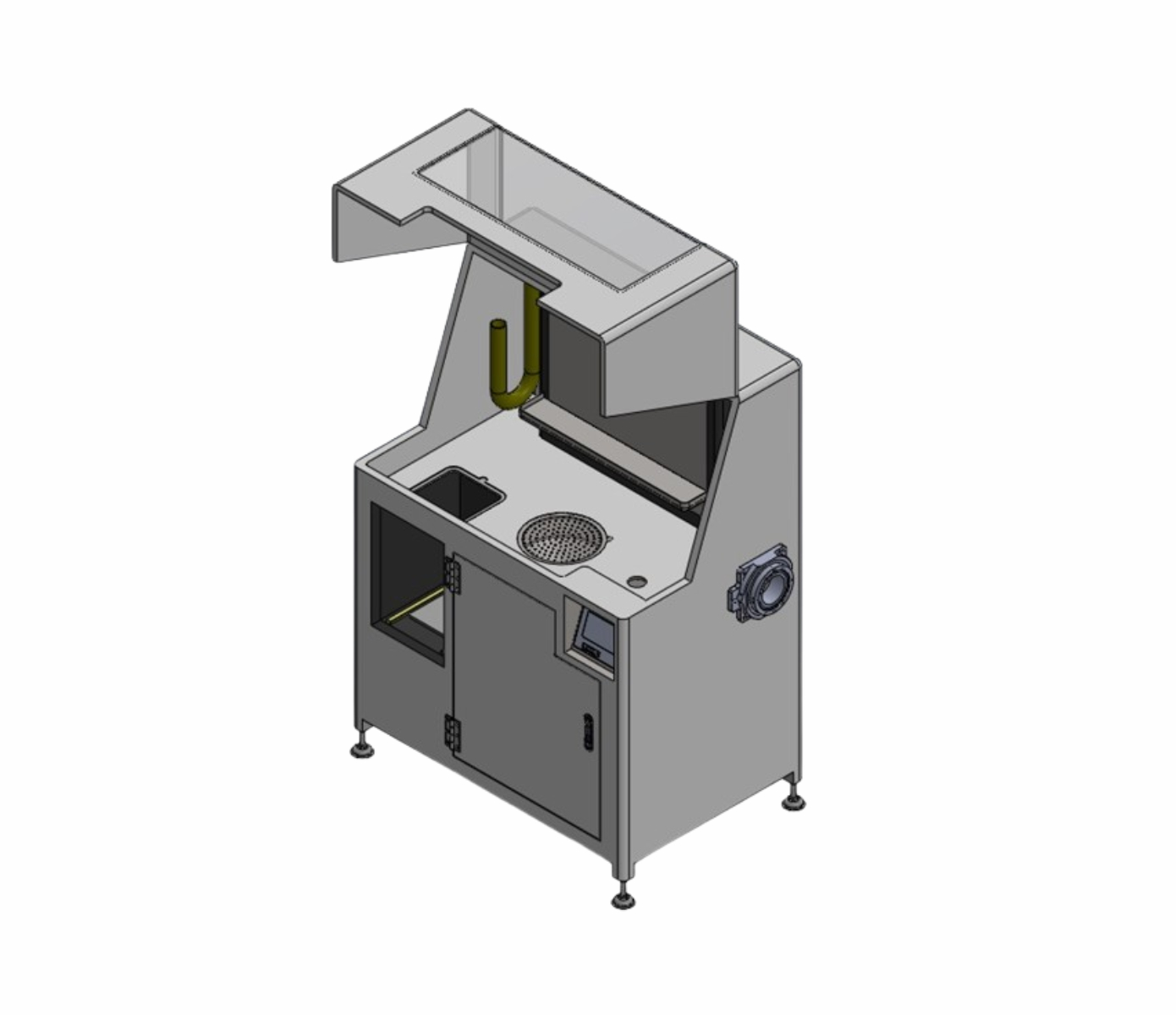

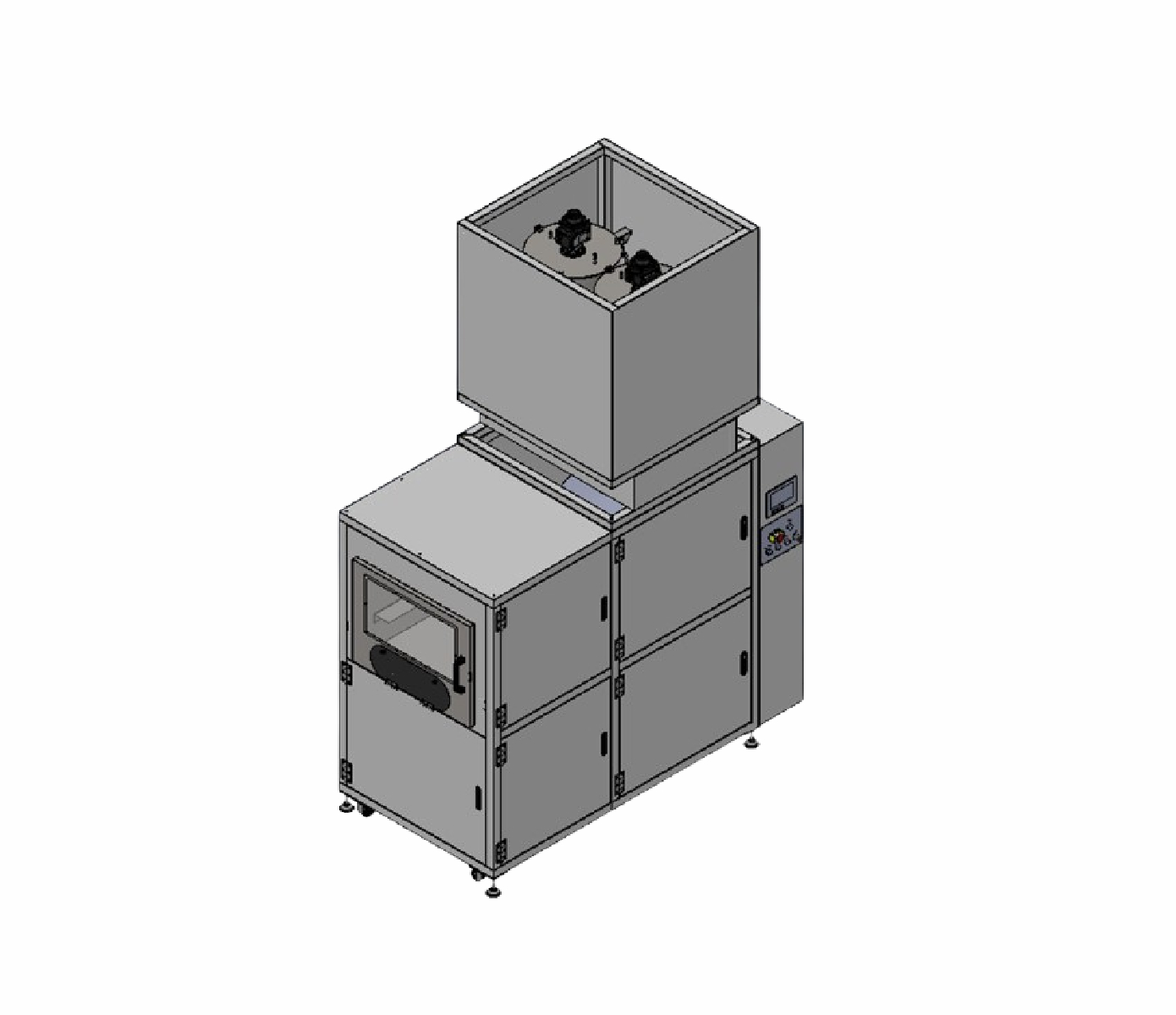

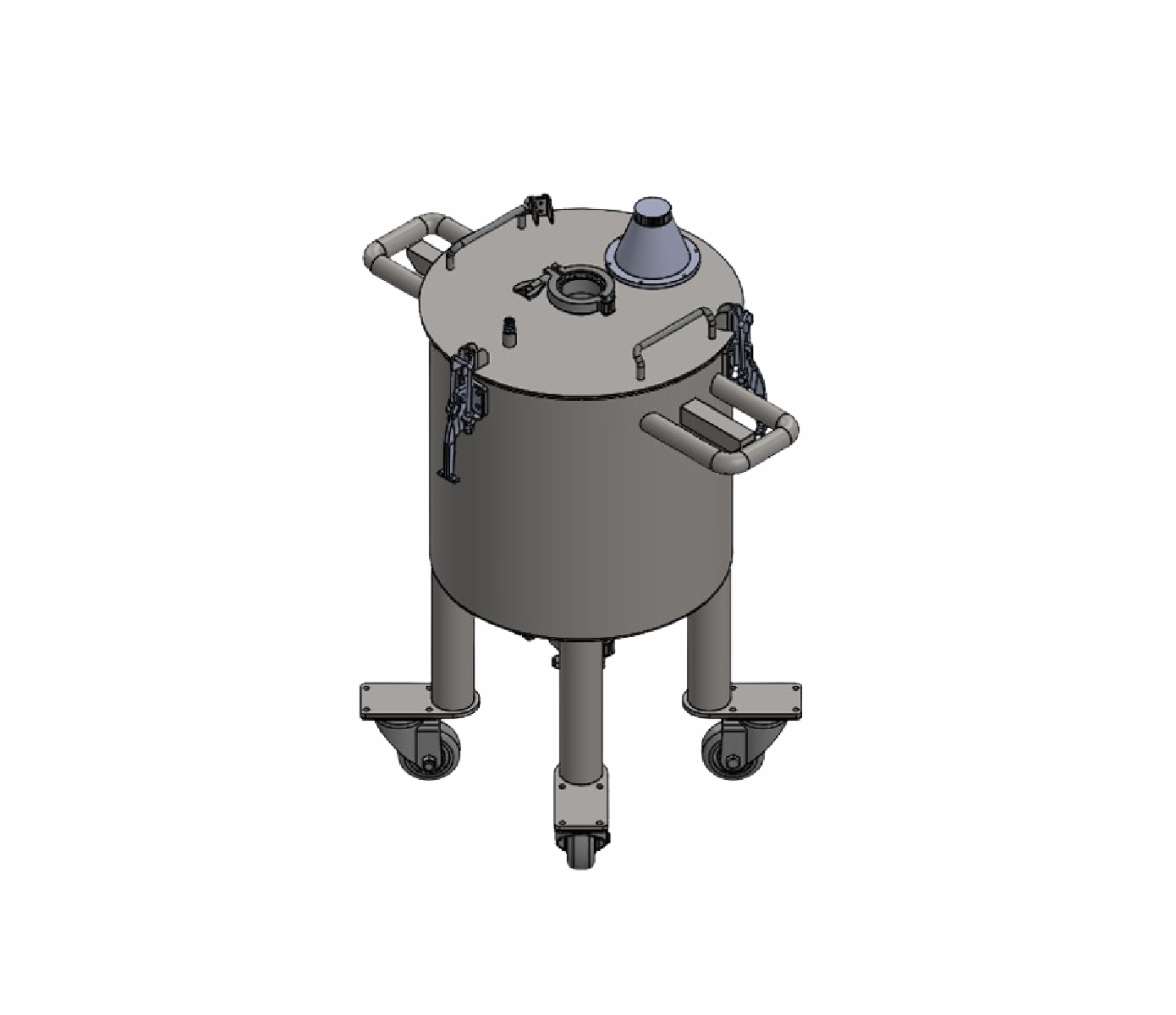

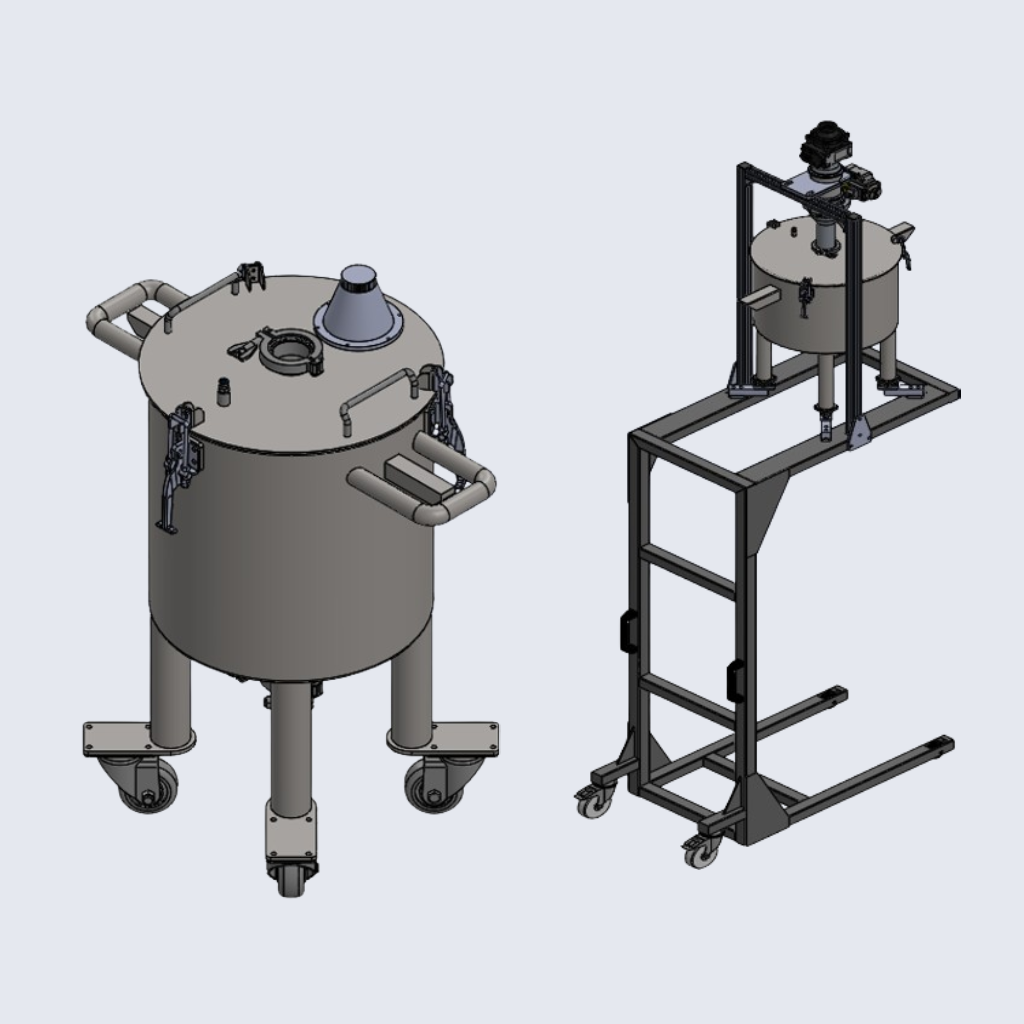

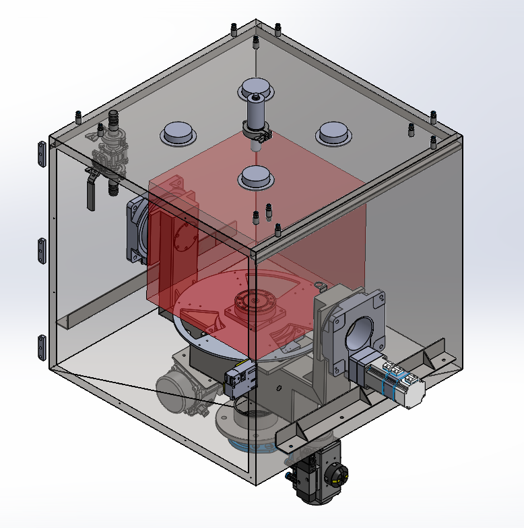

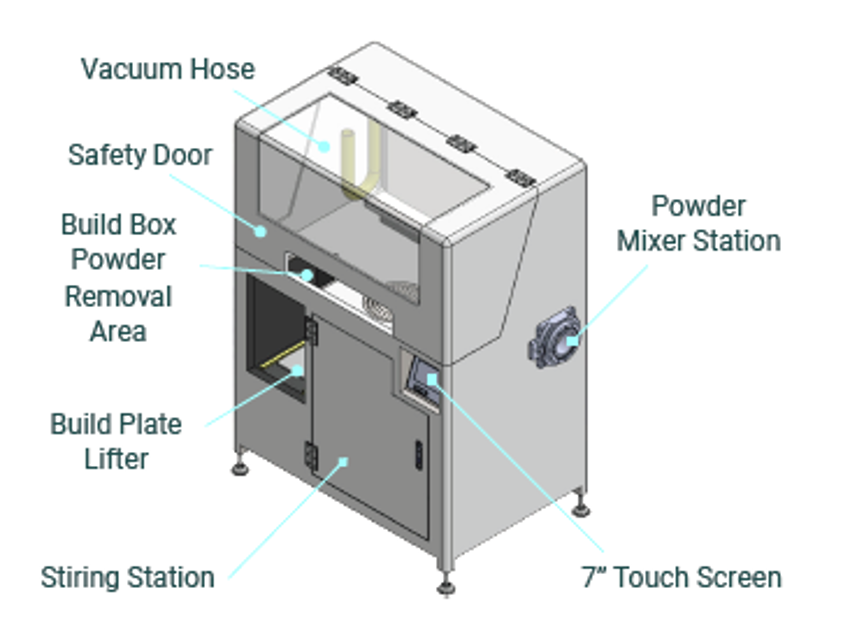

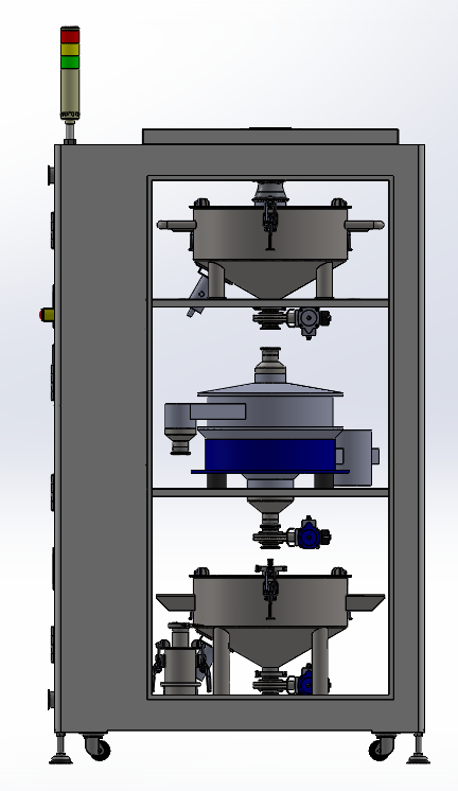

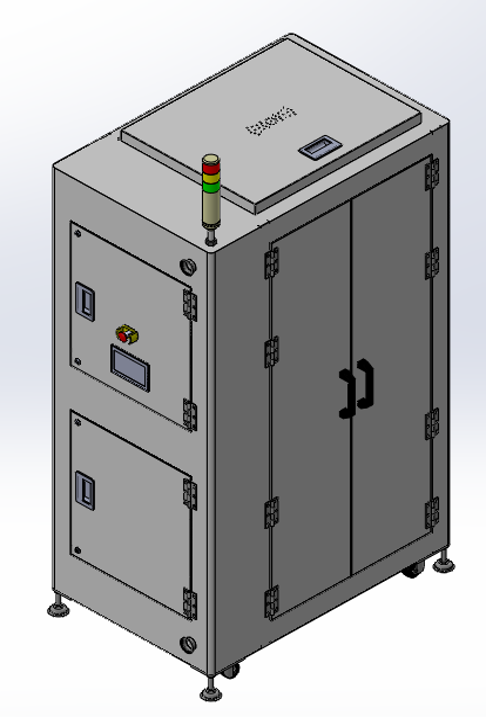

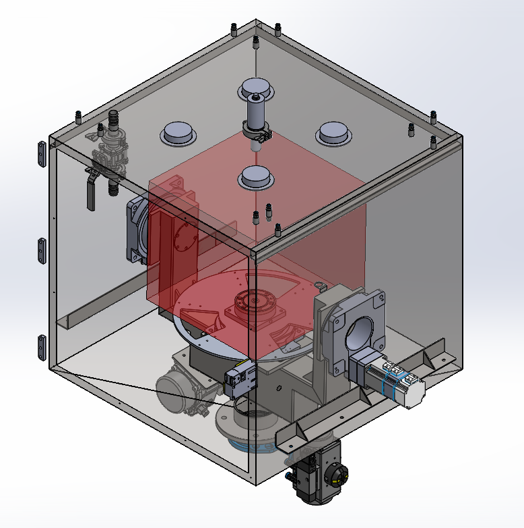

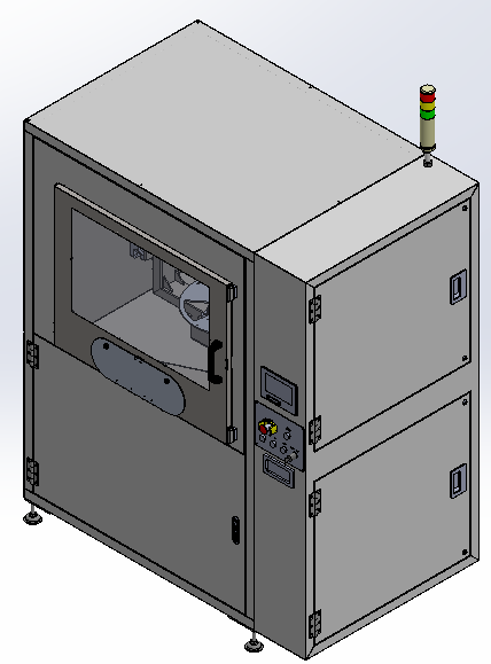

We are pioneering the future of additive manufacturing by offering cutting-edge powder handling systems, designed to automate and streamline the often cumbersome powder handling process.

Our innovative solutions are set to transform the powder handling process such as de-powdering, sieving and filling the powder, making it more efficient, high quality, and cost-effective. Our systems are engineered to optimize the entire workflow, from powder storage and transport to precise dispensing, ensuring the highest quality results while saving you time and resources.

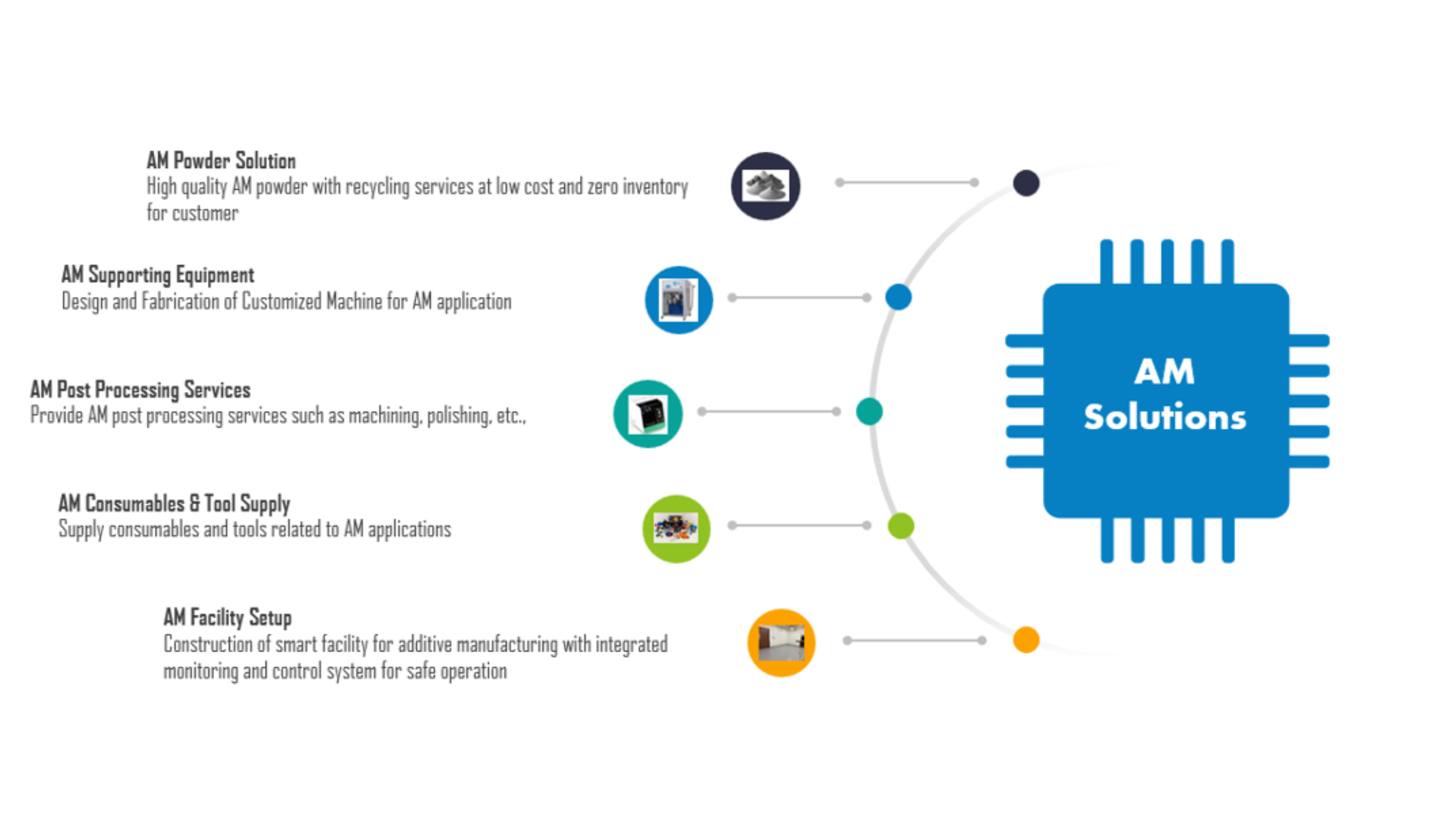

We are one of the first company providing all kind of down stream AM services to support the AM ecosystem across the world.

Join us in embracing the next evolution of additive manufacturing with AECSS – where innovation meets efficiency.