DISCOVER SUCCESS STORIES

Explore our case studies to witness how AECSS engineers solutions, transforms challenges into achievements, and empowers industries to thrive

© 2024 AECSS. All Rights Reserved.

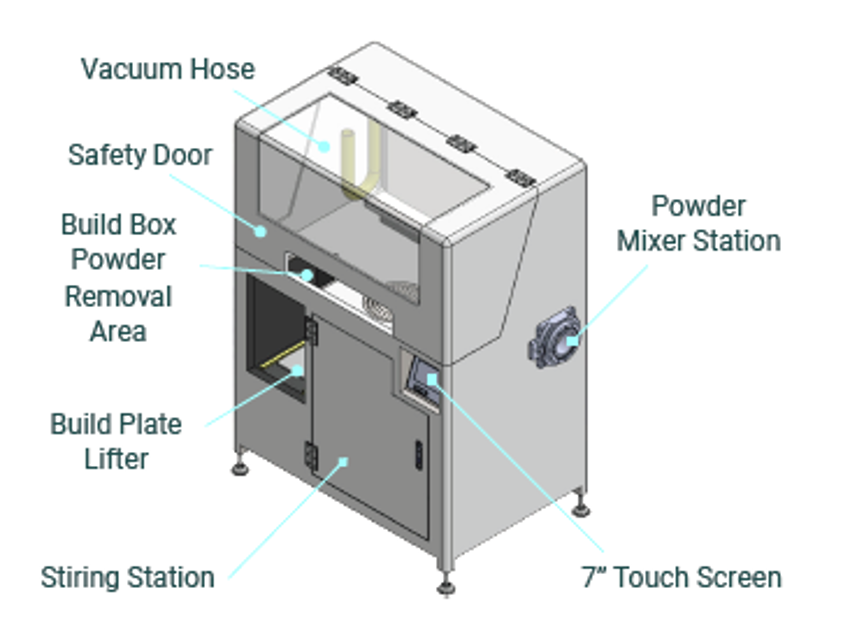

We also fabricate and supply other supporting equipment such as downdraft table, electrical lifter, wet & dry vacuum system, etc.

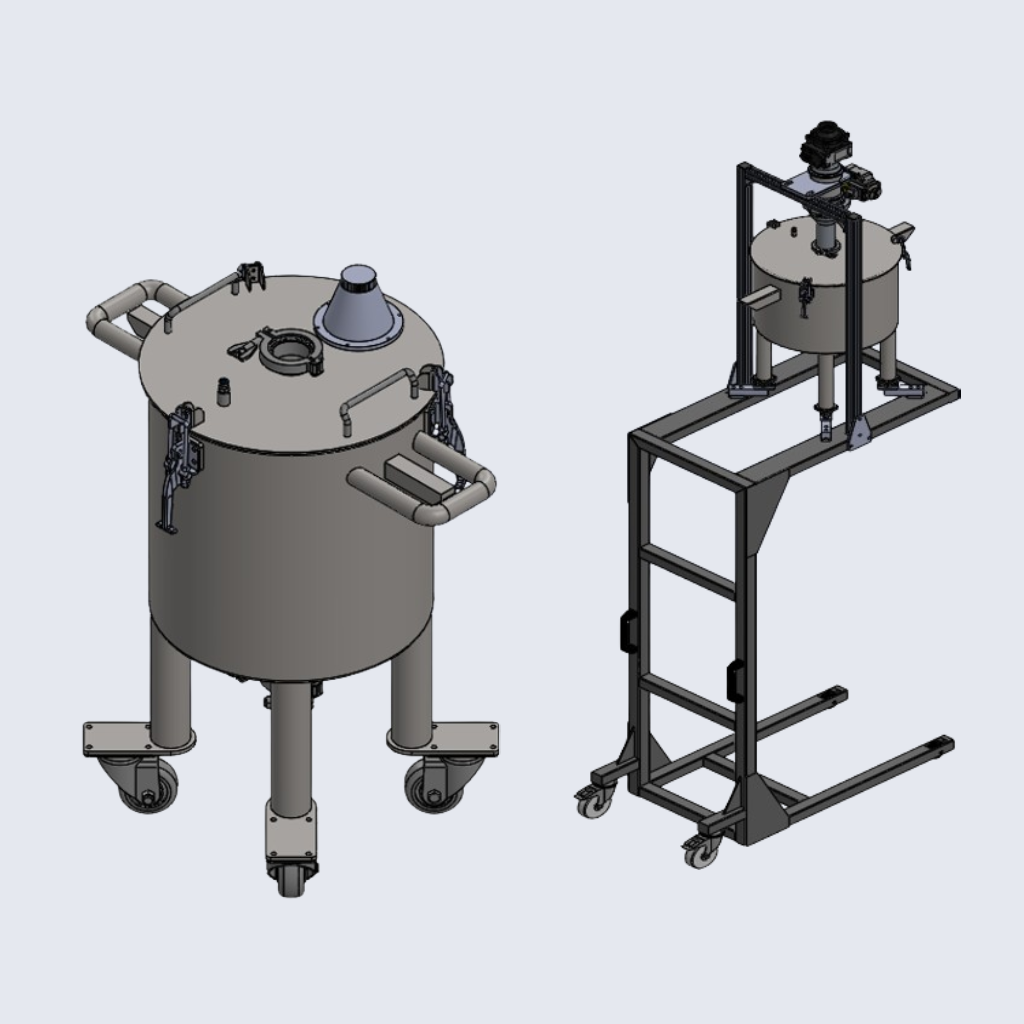

AECSS offers advanced solutions in powder handling for additive manufacturing. Our specialized Powder Transfer Stations and Storage Hoppers are designed to optimize the handling, storage, and transfer of powders in your additive manufacturing processes.

At AECSS, we recognize the critical role of proper powder handling in additive manufacturing. Our Transfer Stations and Storage Hoppers are meticulously designed to streamline your operations, ensuring precision, safety, and efficiency in powder management.

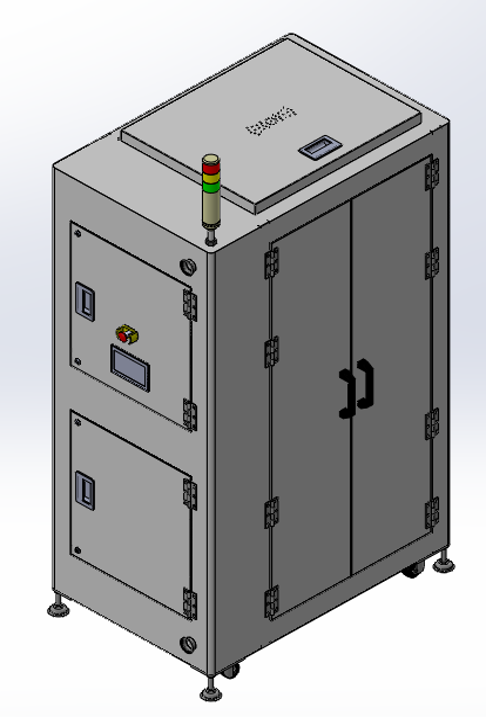

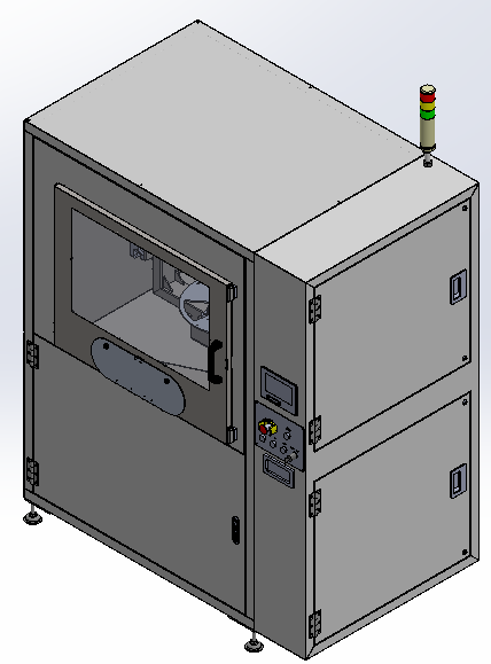

This innovative system offers unmatched efficiency, compactness, and automation to streamline your production while ensuring top-quality results!

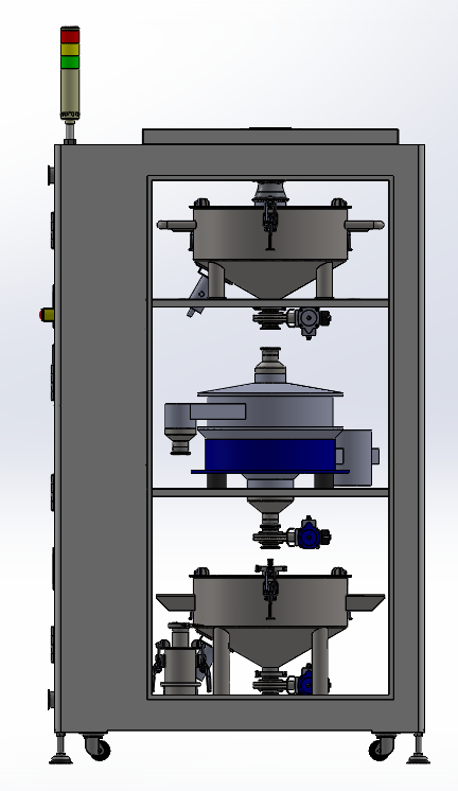

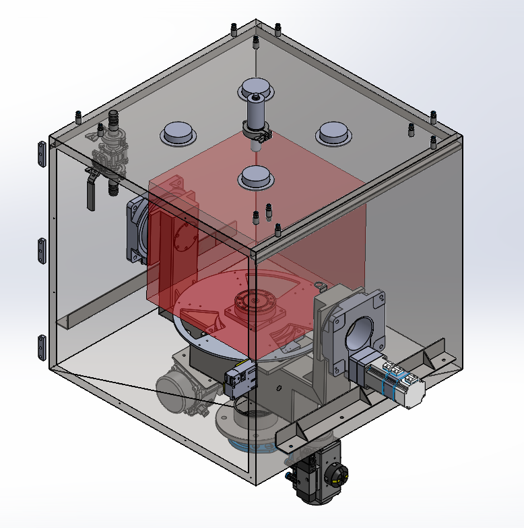

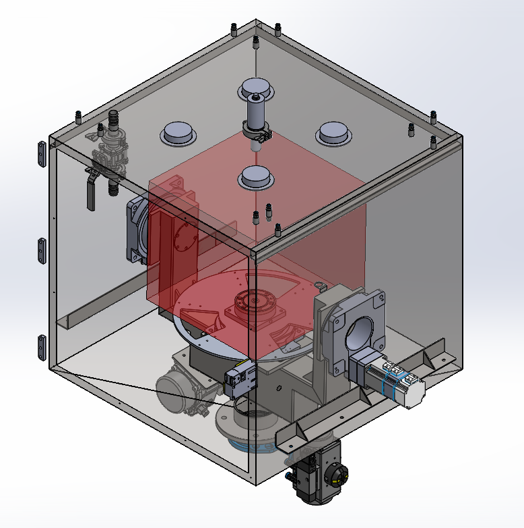

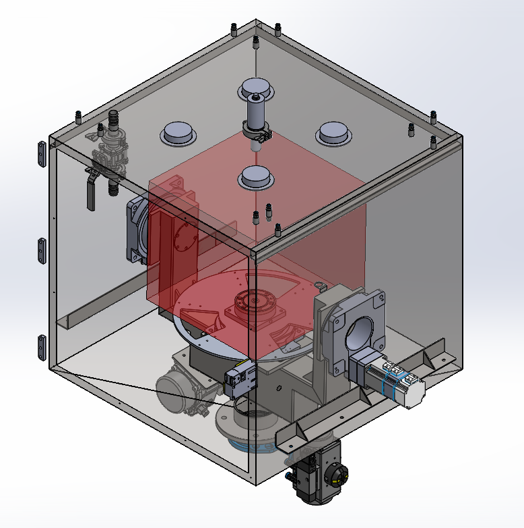

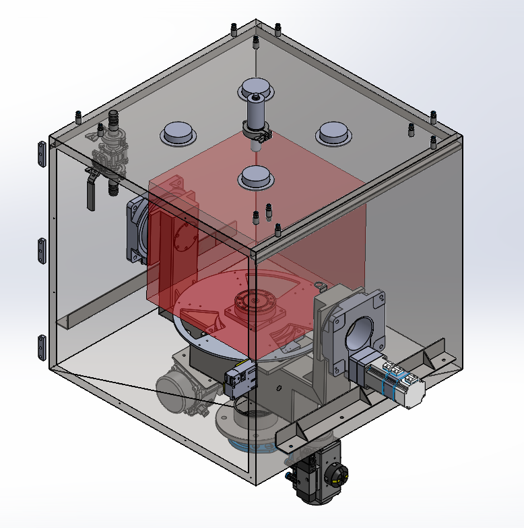

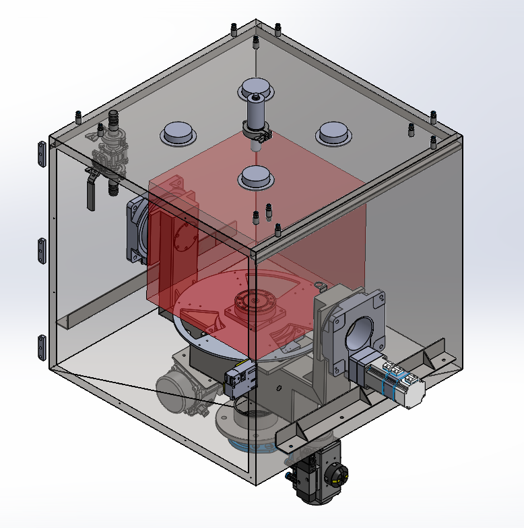

Revolutionize your metal additive manufacturing process with our state-of-the-art Metal Powder Reclaiming System. Our innovative solution is engineered to fully automate every aspect of powder handling, from removal to transfer, sieving, mixing, and seamless loading into 3D printers. Here’s what makes our system stand out:

Our machines ensure efficient and thorough sieving, reclaiming valuable powders for reuse in additive manufacturing processes.

Optimize resources and reduce material waste by reclaiming powders, contributing to a more sustainable and cost-efficient production cycle.

Customizable options allow for adaptable sieving processes, ensuring precise particle separation for optimal powder reuse.